Saint Gobain™ Conductive Silicones

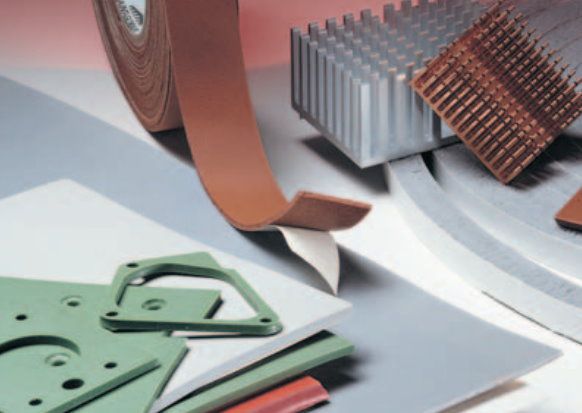

TF1818 is a smooth, calender-coated silicone product that offers great conformability, cut-through resistance and dielectric strength while maintaining a low level of thermal resistance.

TF1867, 1869, 1877, 1879 and FURO 400 SERIES are thermally - conductive silicone coated fabrics that provide thin, cost-effective heat transfer capability. All are obtained plain or with thermally-conductive pressure-sensitive adhesive on one side.

TC100 is an unsupported, thermally-conductive solid silicone available in several thicknesses, providing thermal and mechanical protection to electronic devices.

TC100U, in the uncured state, is an effective system for bonding printed circuit boards, heat sinks, and electronic components to a variety of substrates. Refrigerated storage is required.

EC102 is an electrically-conductive, 50 durometer solid silicone rubber that performs three distinct functions. The carbon filler in it allows it to act as a low amperage conductor. It shields RF and EM interference. And it protects against the development of electrostatic discharge.

Adhesive Backings

Auburn can apply pressure sensitive silicone or acrylic adhesives to standard sheets (36" x 36" or 24" x 24") or continuous length rolls at 36° wide. The self-adhering materials permit substantial savings because they are easy to apply, simplify production, and eliminate the high cost of bonding. SP-2021 Silicone Adhesive withstands the same temperature extremes, -100° F to +500° F, as the silicone rubber sheet. AP-2022 Acrylic adhesive, whose temperature range is -40° F to +300°F, offers the same advantage of twice the adhesion to steel and a longer shelf life than silicone adhesive.

Hi-Temp Acrylic Adhesive, newly released, is capable of withstanding temperature of 450F, while providing the high-bonding strength of acrylic adhesive. All of these above-mentioned electrically or thermally conductive silicones from Auburn are readily available either plain or with an adhesive backing applied to one, or in some cases, both sides. Self-adhering adhesive-backed sheets are protected by an easy-to-remove peel-off liner for application to a clean, dry, degreased surface.