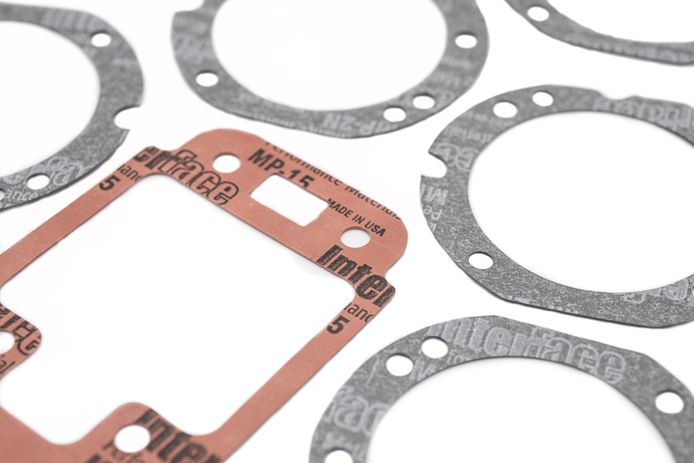

Standard Products

MP-15 from Auburn is designed for heavy-duty applications including die cut compressor gaskets, die cut diesel engine gaskets, and others. It has excellent low flange pressure sealability and bolt torque retention. It is intended for applications with short duration maximum temperatures up to 205°C (400°F).

MP-2N from Auburn is specifically engineered for die cut gaskets for automotive powertrains, marine and small engines. It provides excellent sealability for coolant lubrication, and induction systems. It conforms well to irregular flange surfaces and is intended for applications with short duration maximum temperatures up to 205°C (400°F).

PF-4N has a fully cured nitrile butadiene rubber binder for maximum fluid resistance. It has provides excellent sealability for die cut gaskets in a variety of environments and flange conditions. It is intended for applications with short duration maximum temperatures up to 290°C (550°F).

PF-4S is designed for various oil, air, and coolant applications that include die cut gaskets for oil pans, front covers, intake manifolds and cut rear seals. It is a replacement for styrene butadiene rubber bound asbestos and non-asbestos calendared sheet materials and offers improved oil sealability over nitrile butadiene bound materials. It is intended for applications with short duration maximum temperatures up to 290°C (550°F).

Auburn is capable of taking any Accopac® material and applying adhesive to one or both of its surfaces. Auburn adhesives are available for both raw materials and finished die cut gaskets including die cut shims, washers, spacers, gaskets and seals. Auburn works with dozens of popular adhesives including:

The use of adhesives has many distinct advantges that include eliminating the messy job of cementing during assembly operations, assuring a uniform amount of adhesive per part, and reducing labor time in assembly operations.

Manufacturing Capabilities

Auburn’s speciality is fabrication of precision die cut gaskets with tight tolerances and clean cut edges for any production quantity from a single piece up to millions. All die cut gaskets are cleaned, inspected and neatly packaged prior to shipment.

Tooling

For a simple part such as a plain die cut washer, a disc, a rectangular pad or a uniform-width strip, a house-tool is very often available at no additional cost. For a more complex part that requires a tool, a steel rule die is built. A steel rule die’s cost is usually quite minimal ($95.00-$125.00 range) and its production time is ordinarily only 1 or 2 days, at which time a first article sample is sent to the customer for a final approval.

Ordering Information and Special Orders

Please contact your Auburn Customer Service Representative to learn more about these products or to obtain material recommendations, product samples, design ideas, or price quotations for either raw materials or custom die cut gaskets.